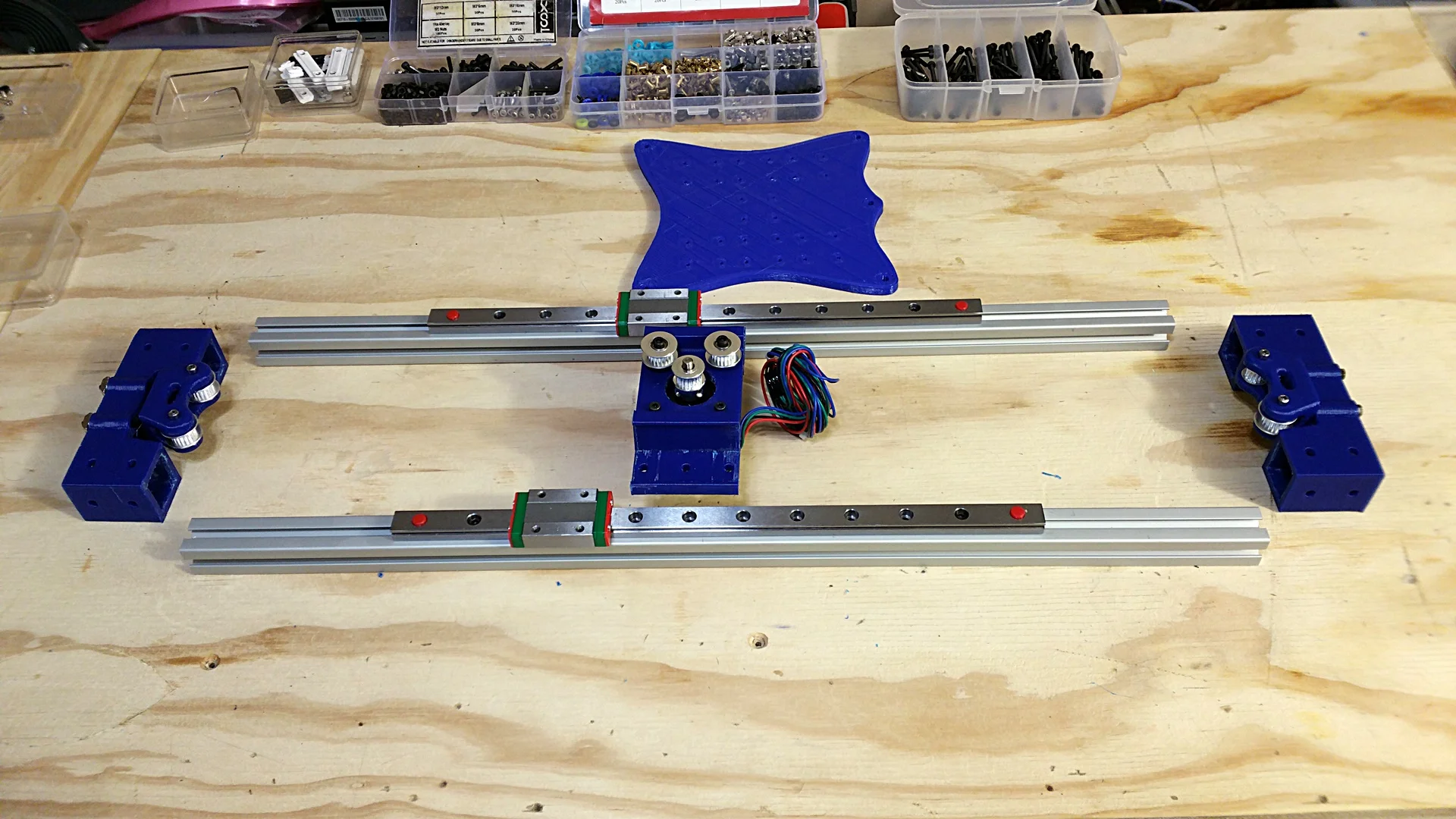

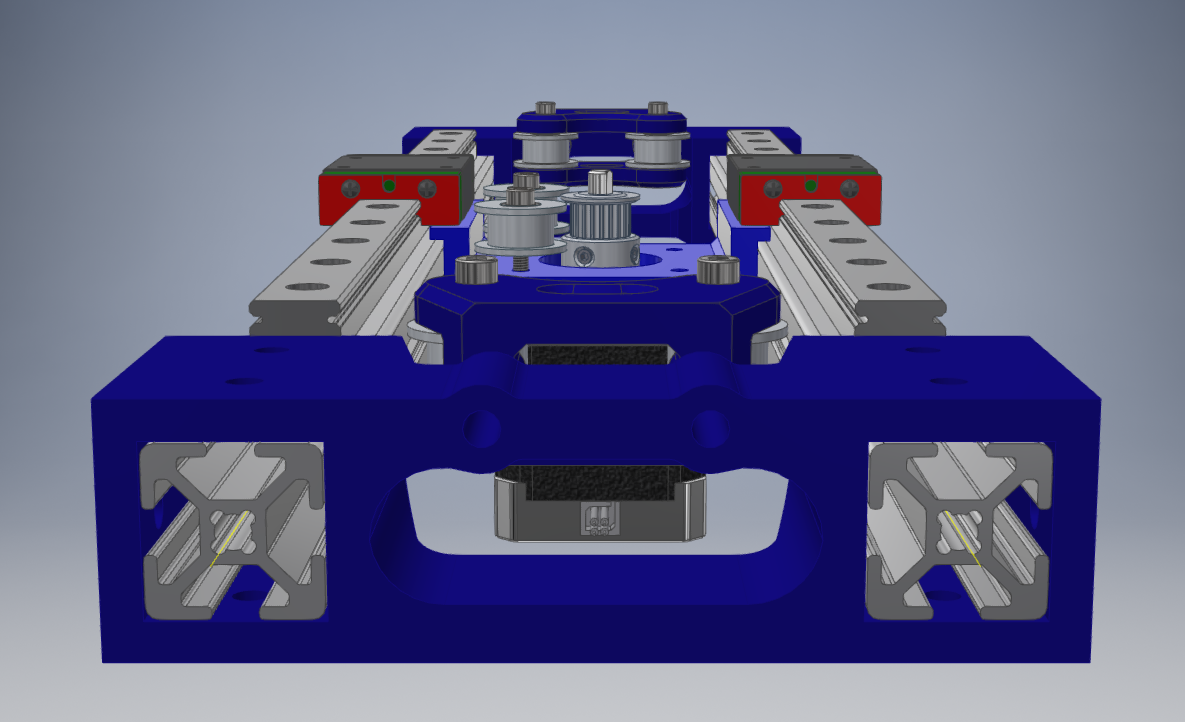

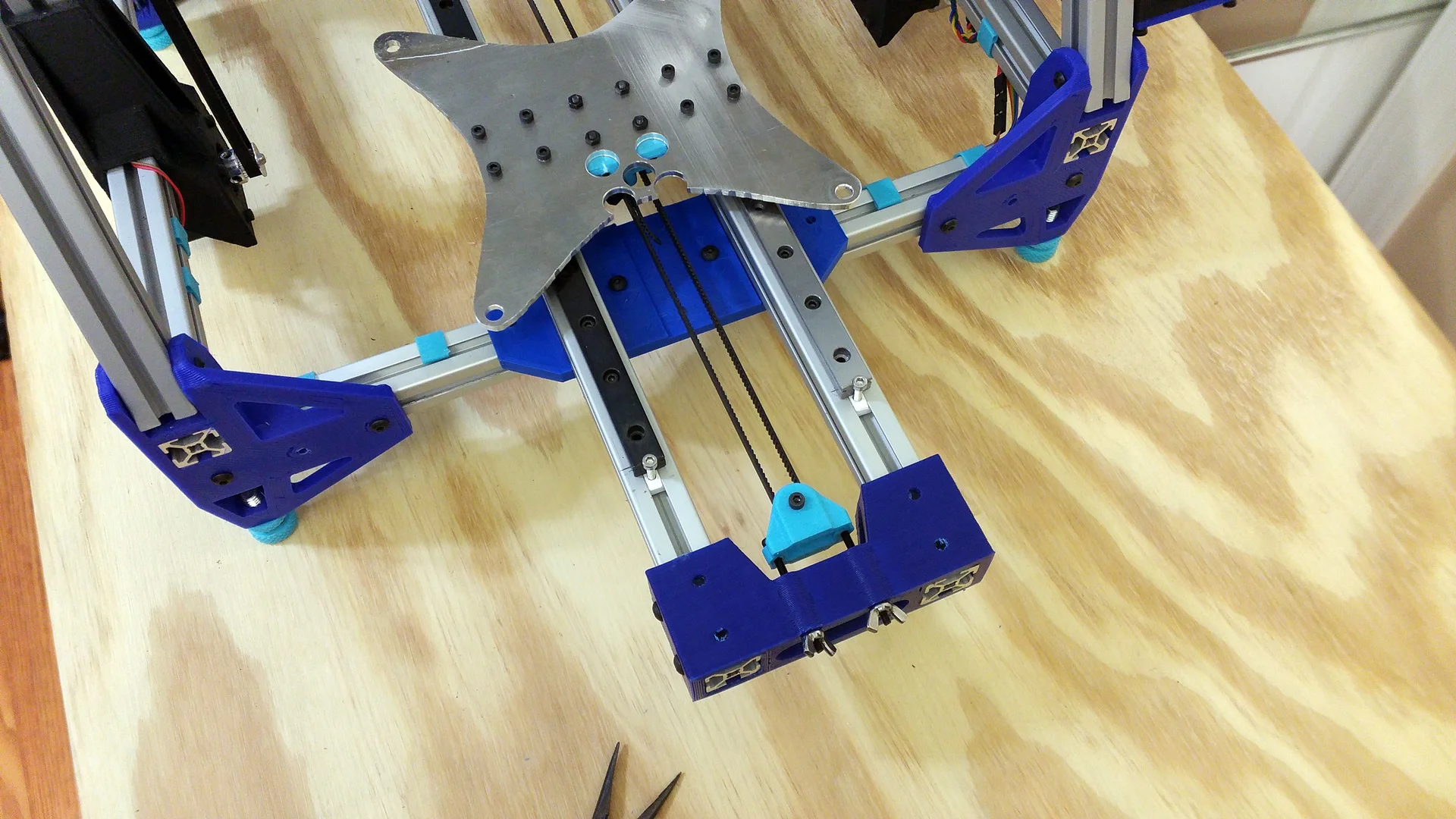

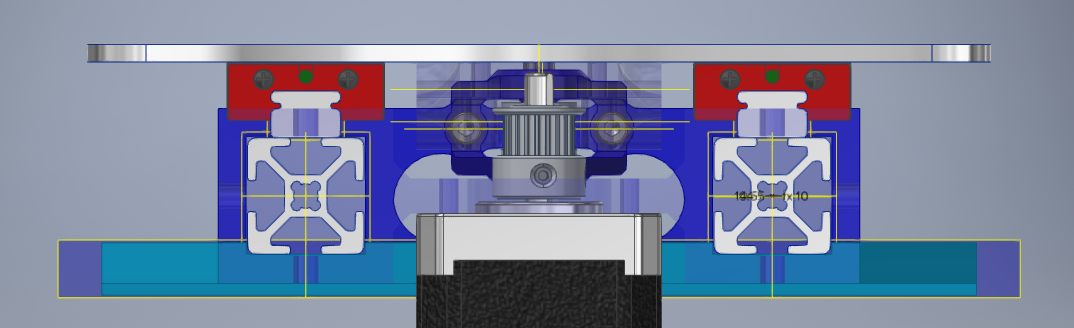

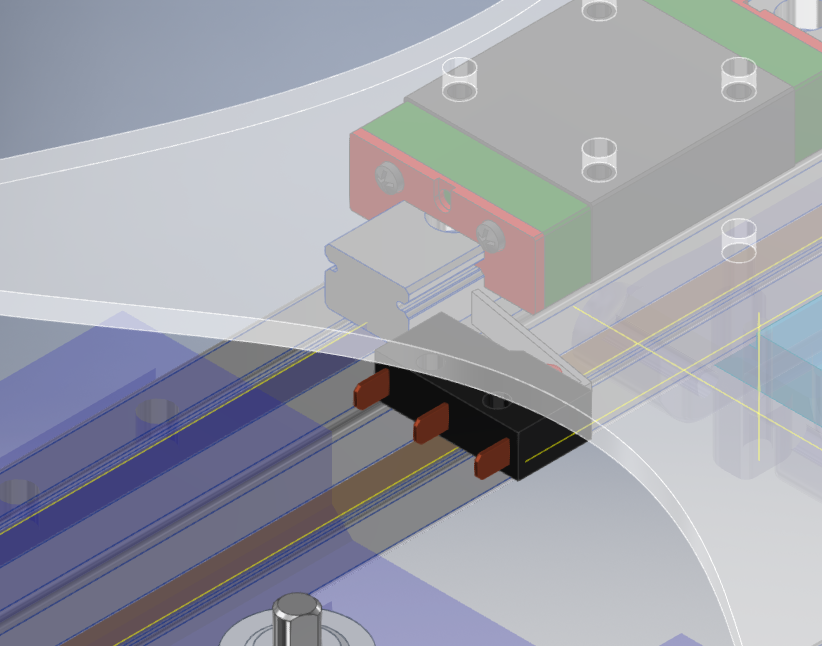

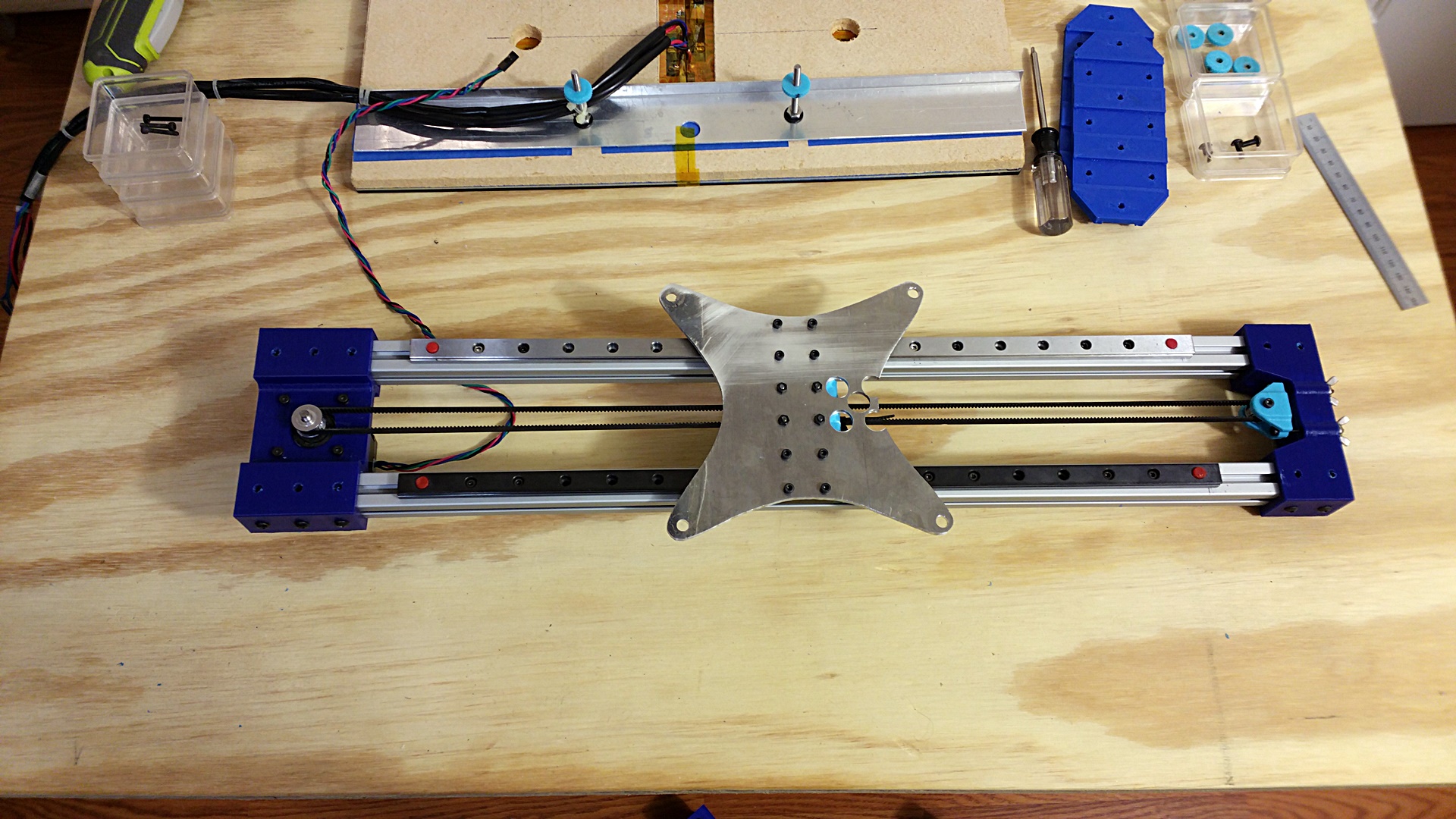

The first prototype parts revealed the Belt Retainer Bracket was hitting the Stepper Drive Pulley.

The entire belt run was moved down ~5mm to increase the clearance between the Belt Retainer Bracket and the Stepper Drive Pulley.

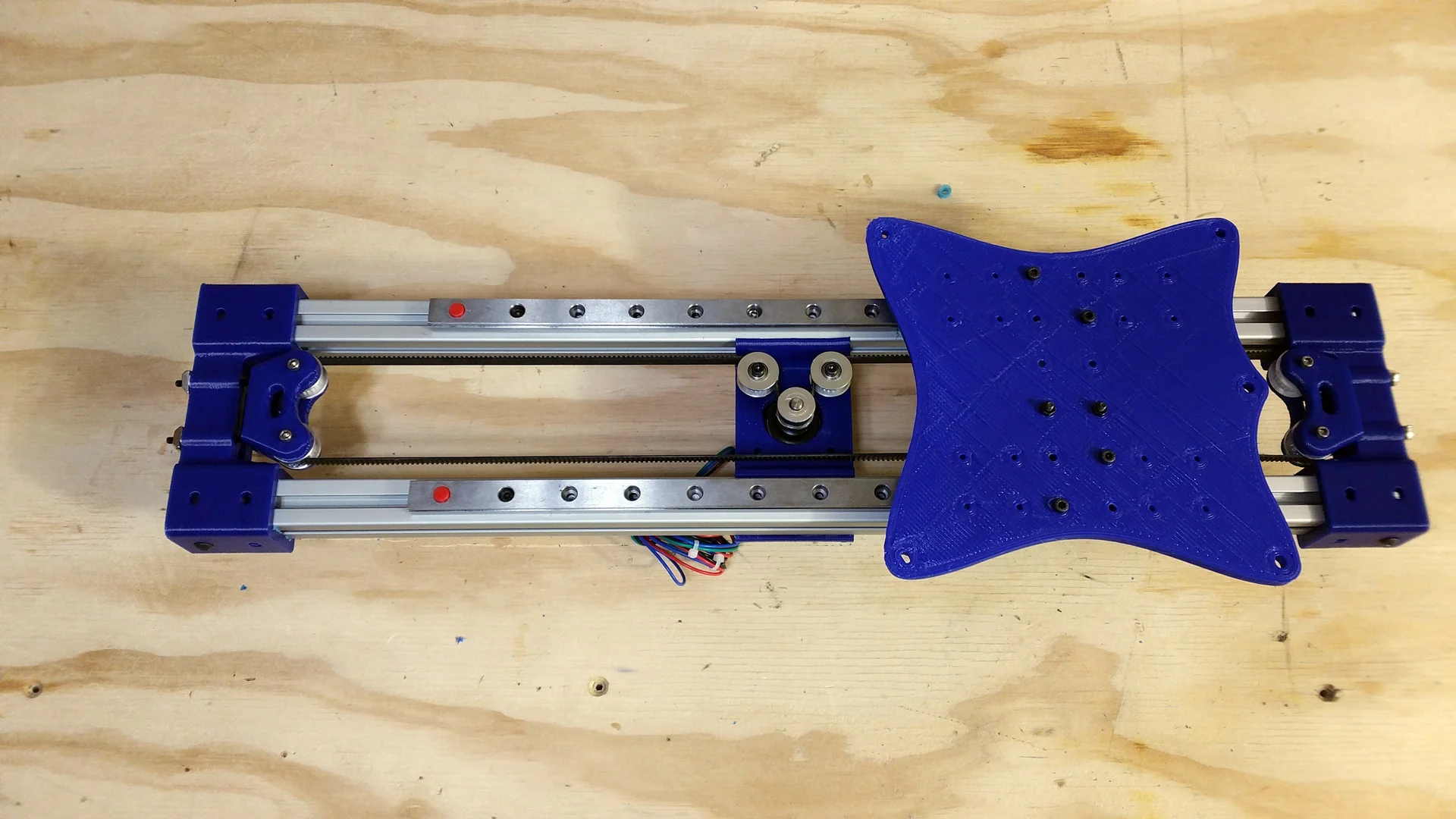

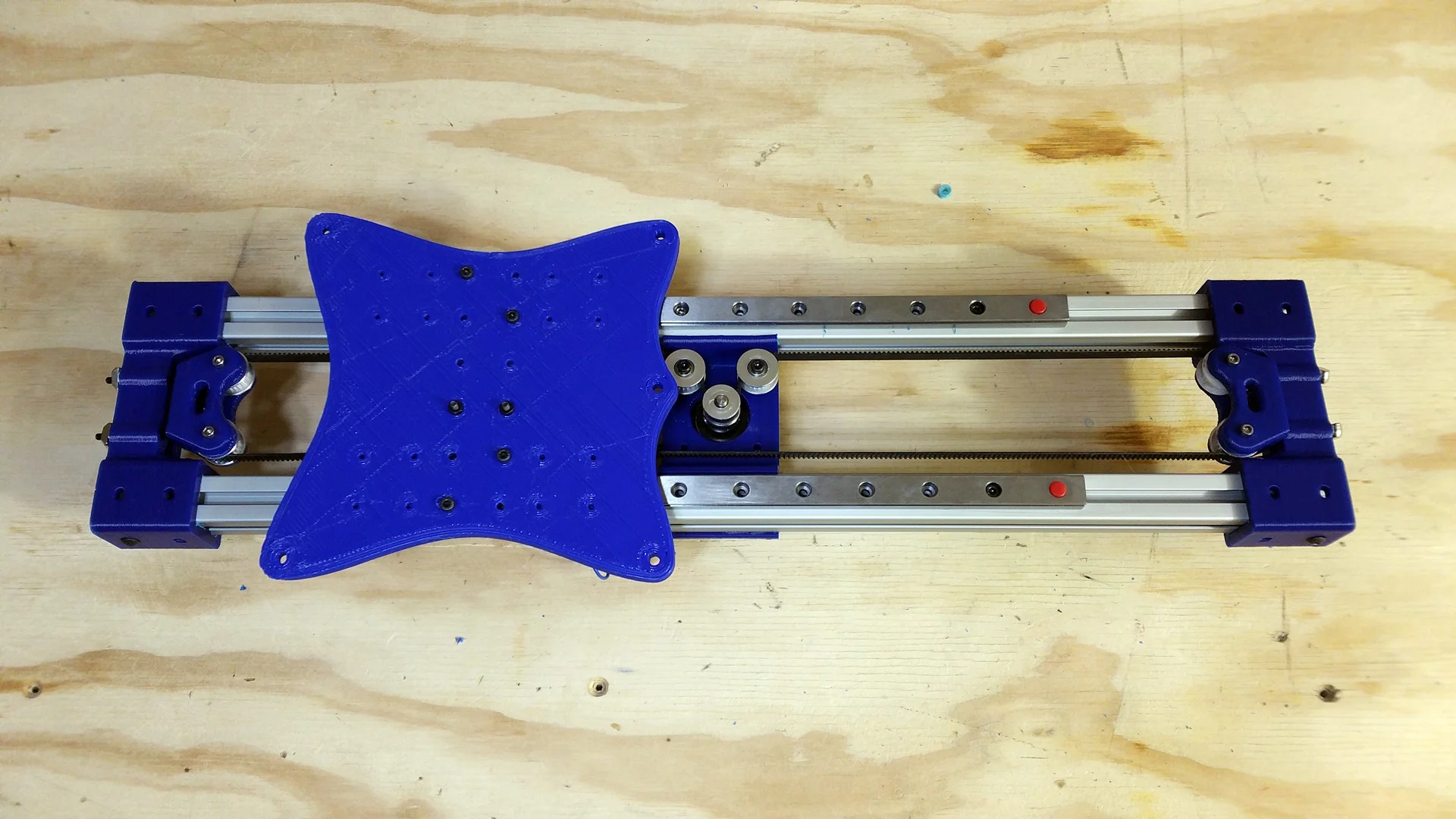

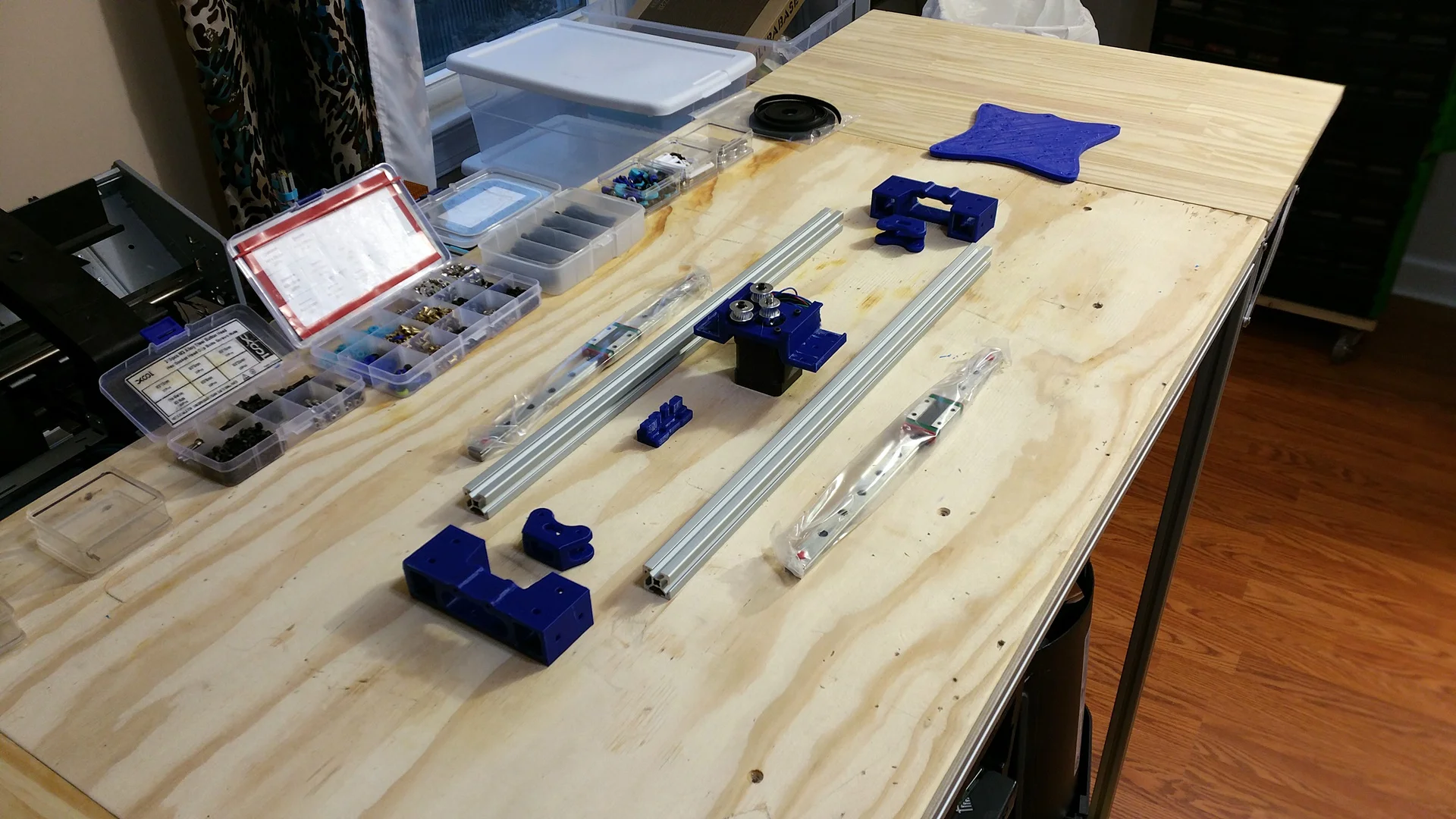

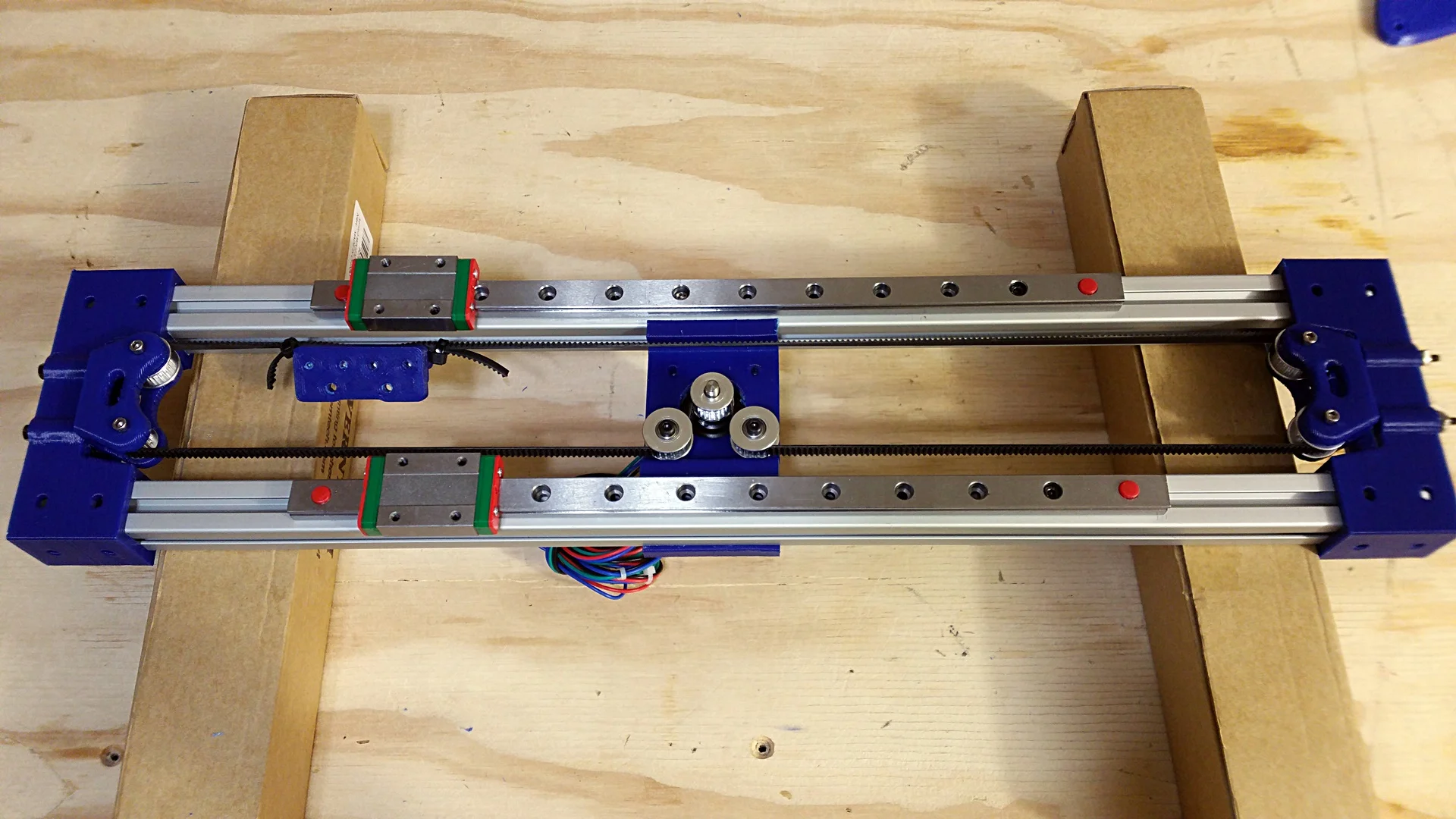

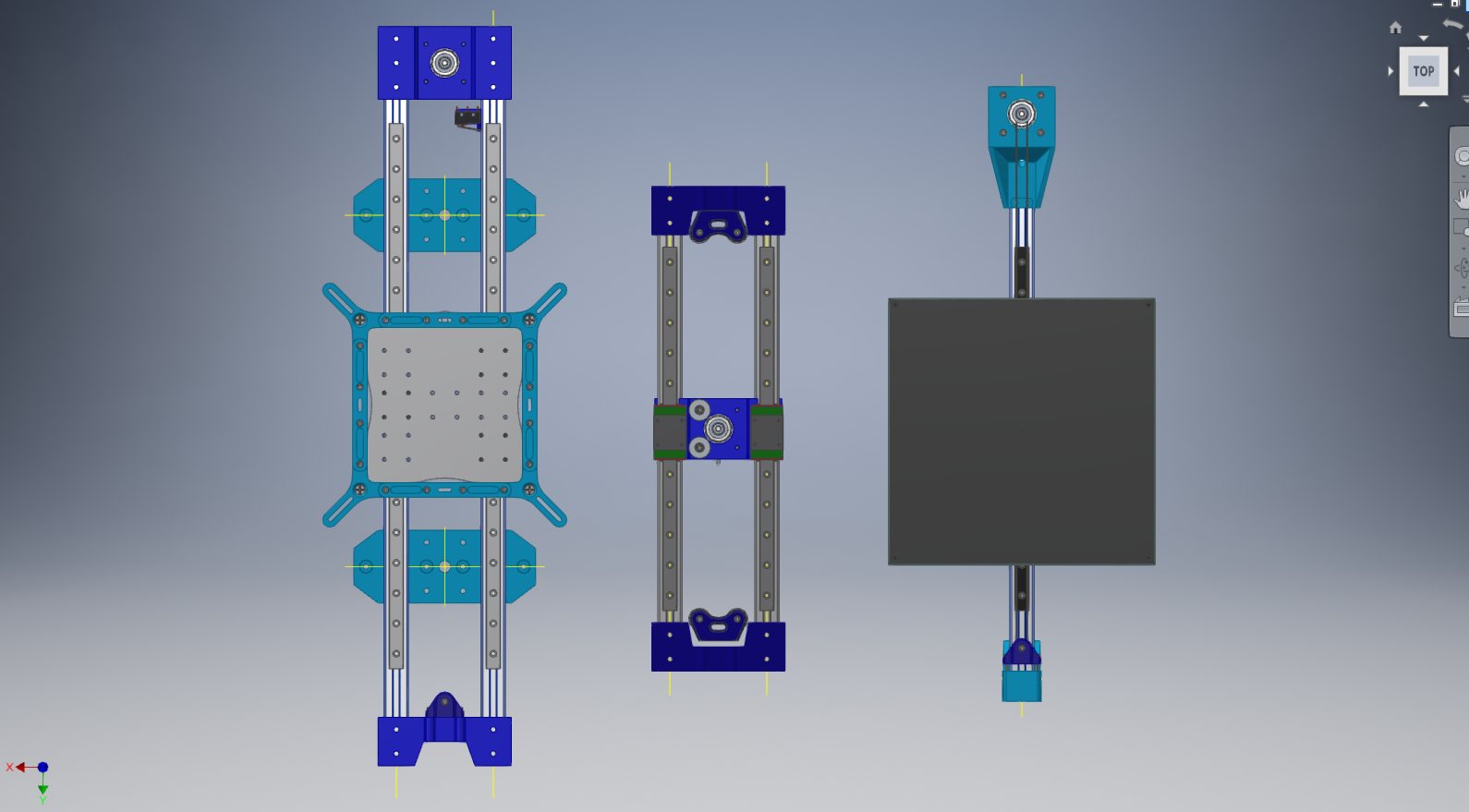

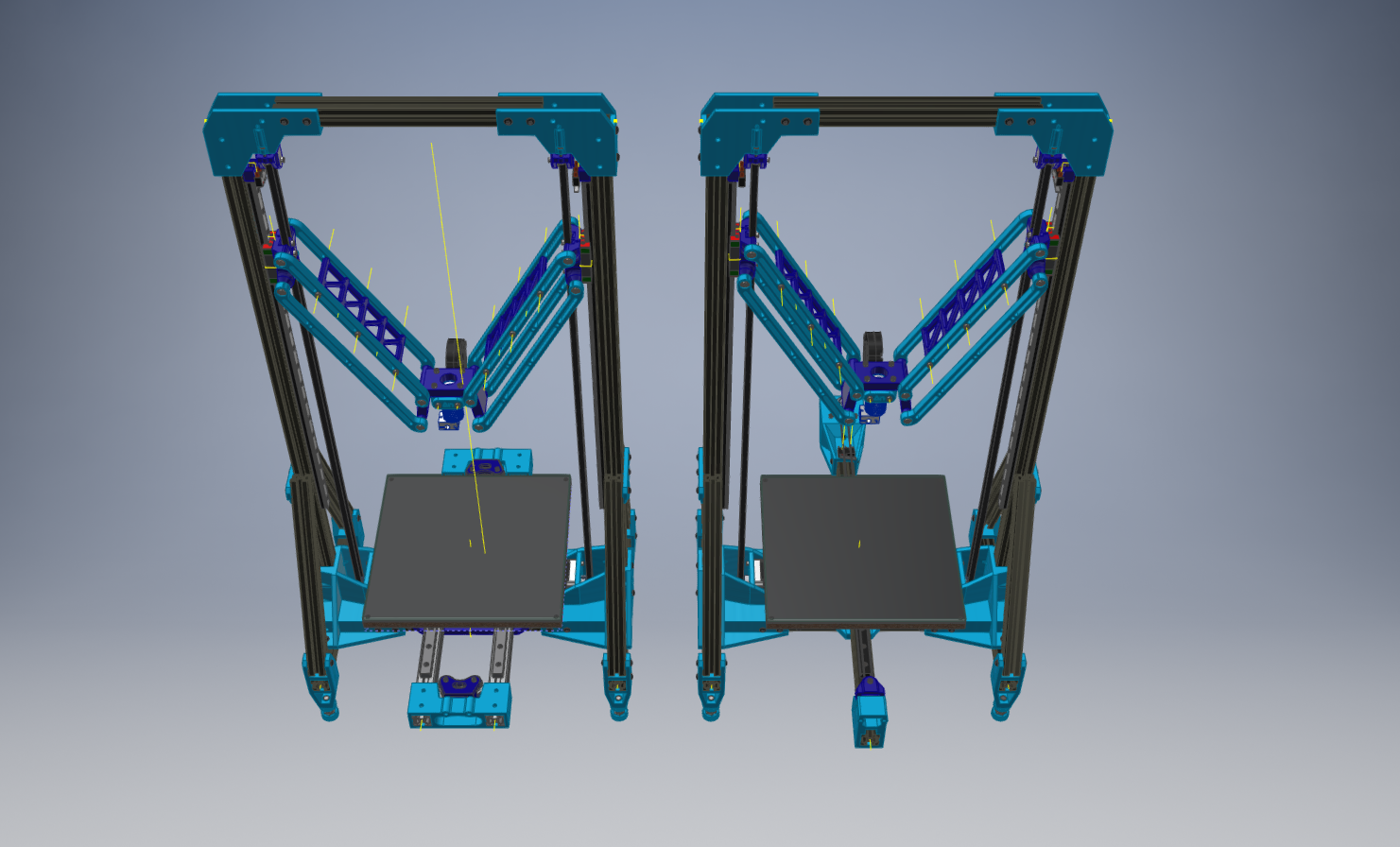

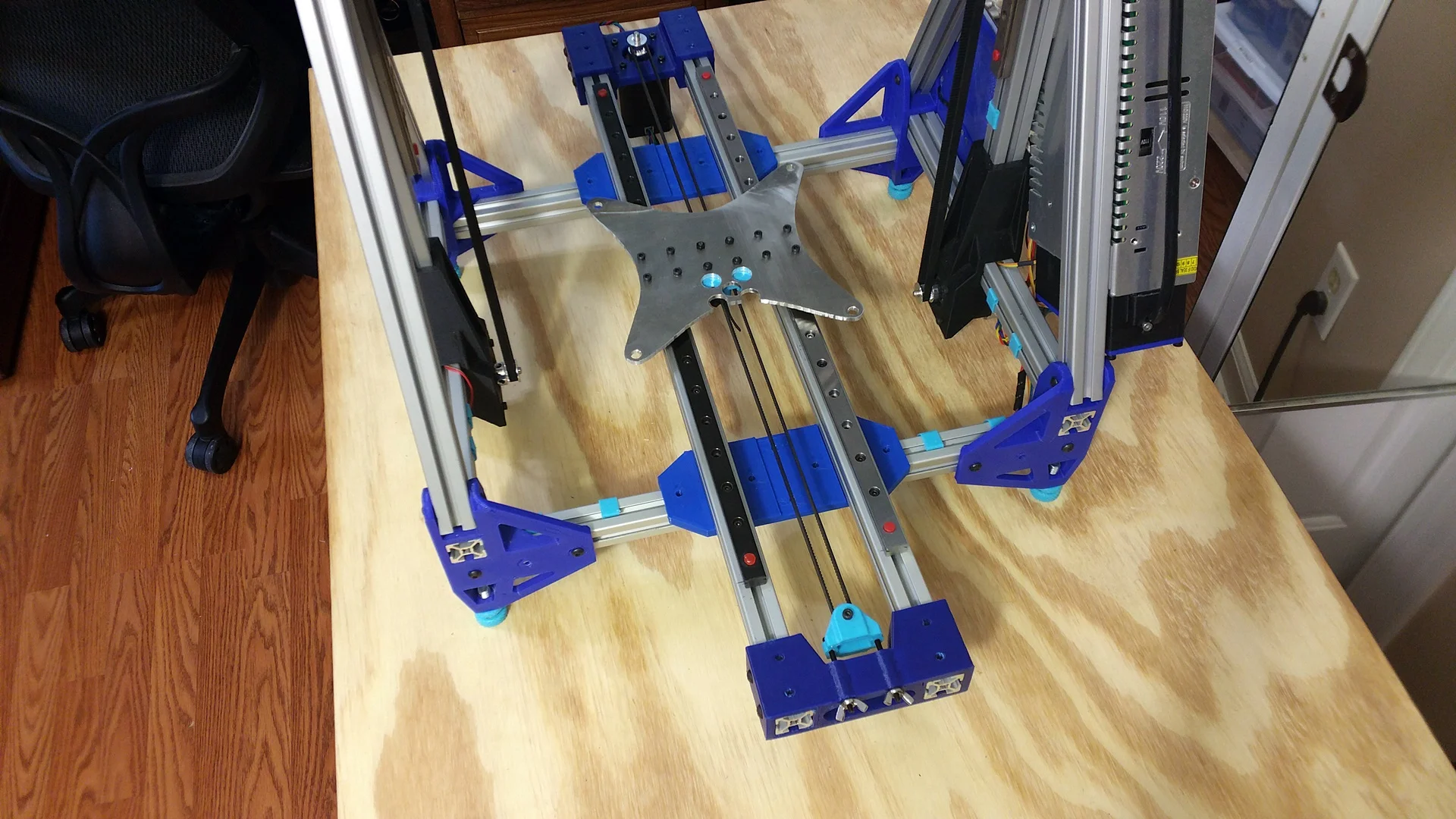

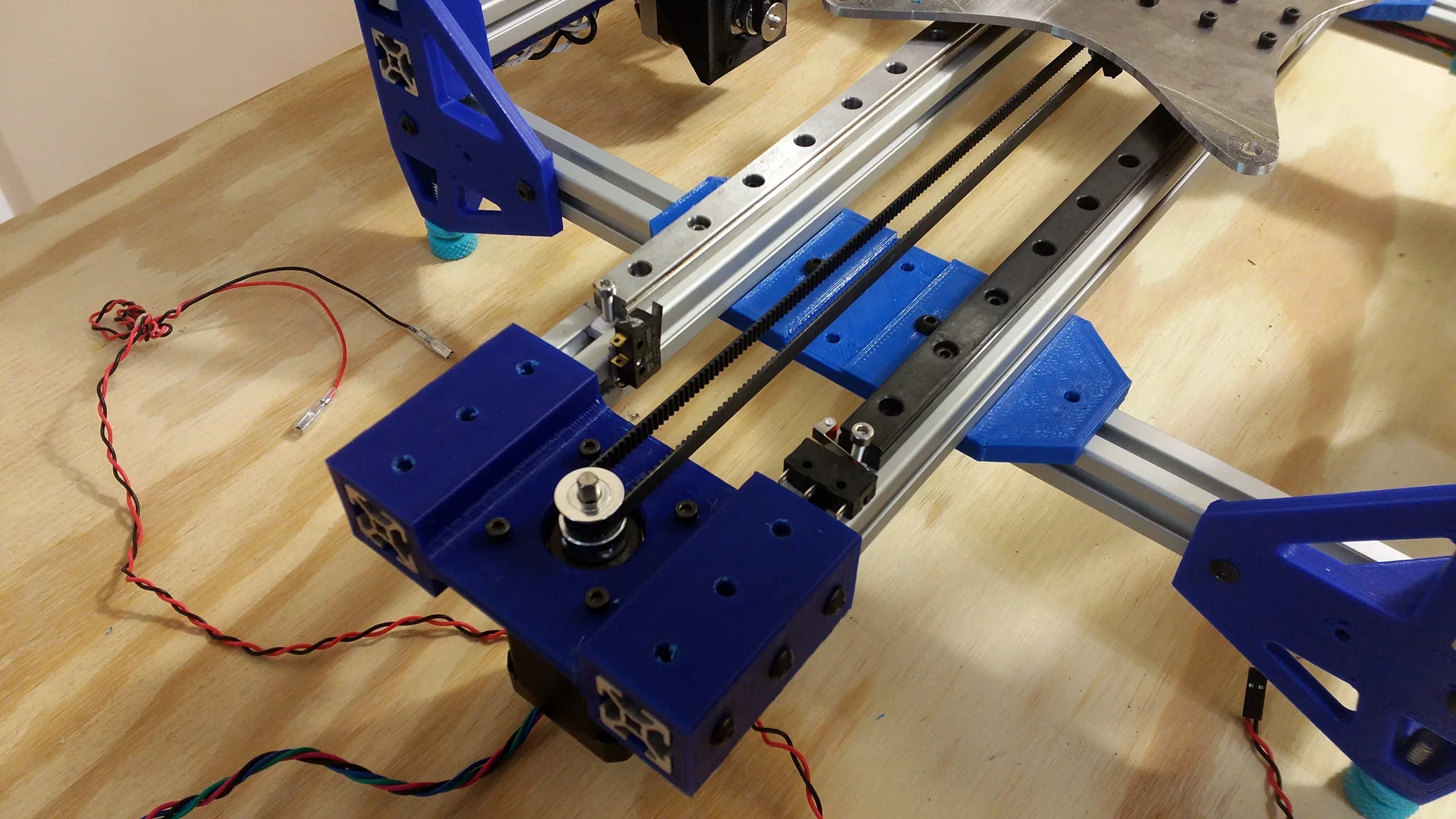

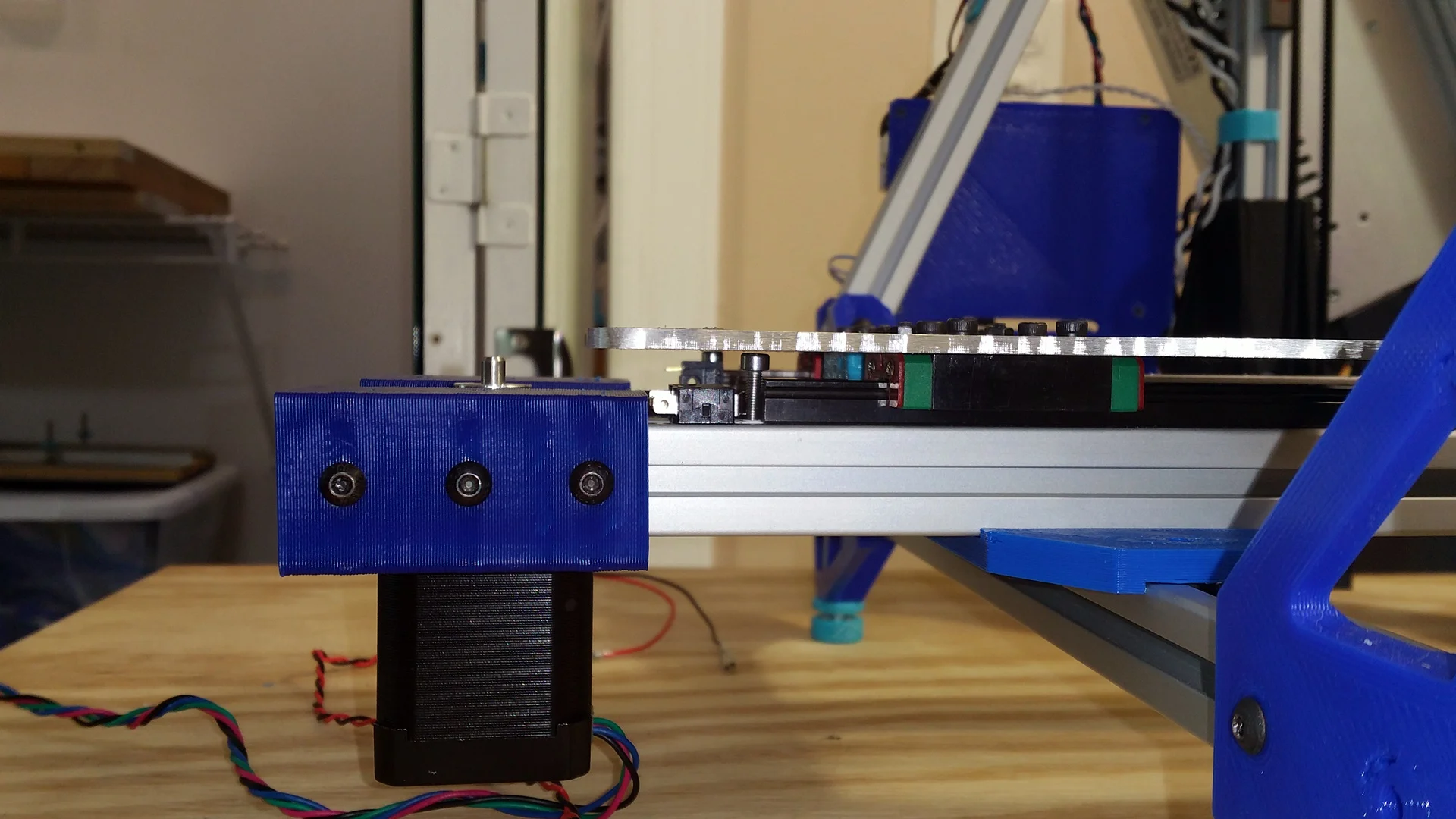

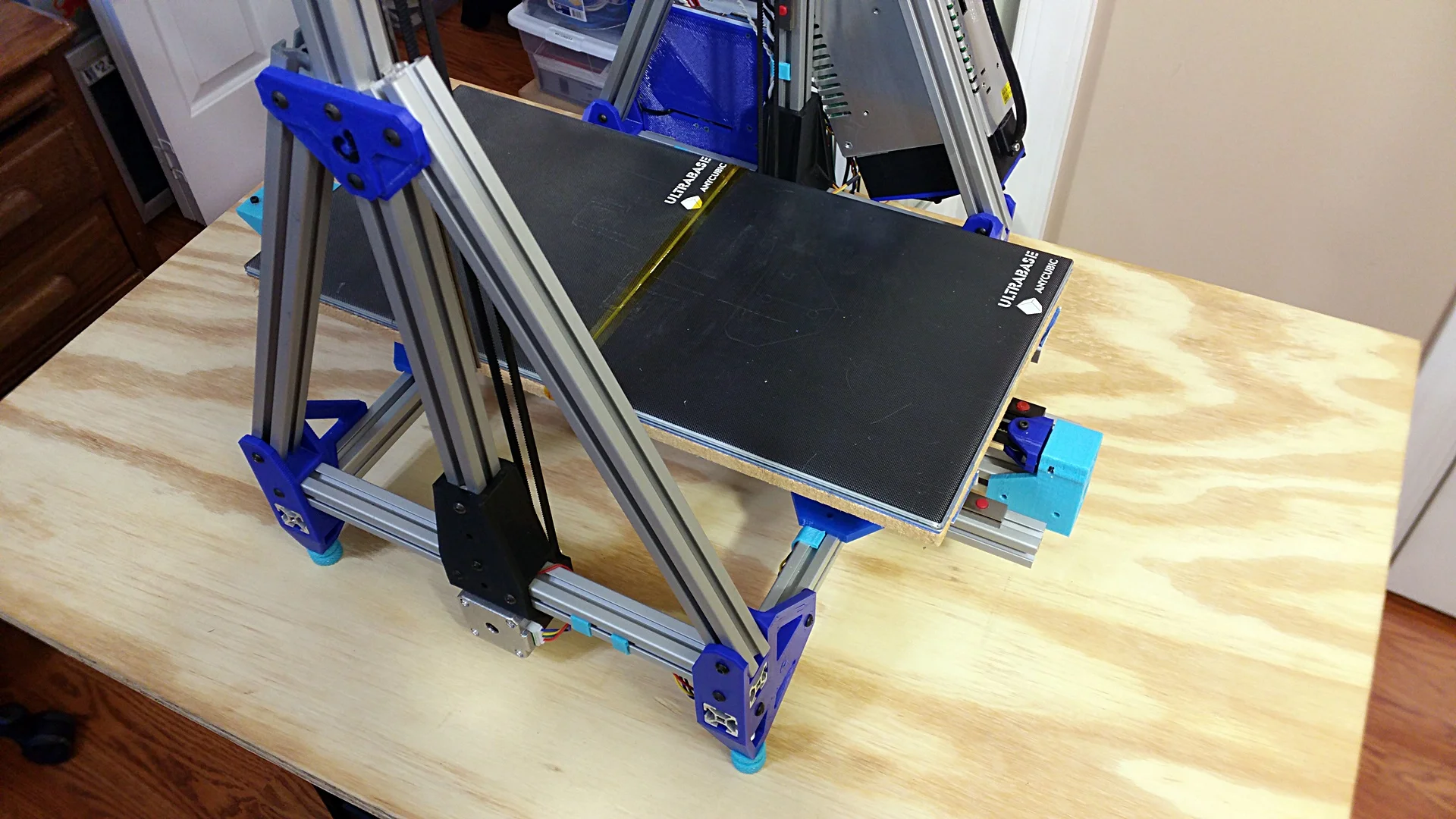

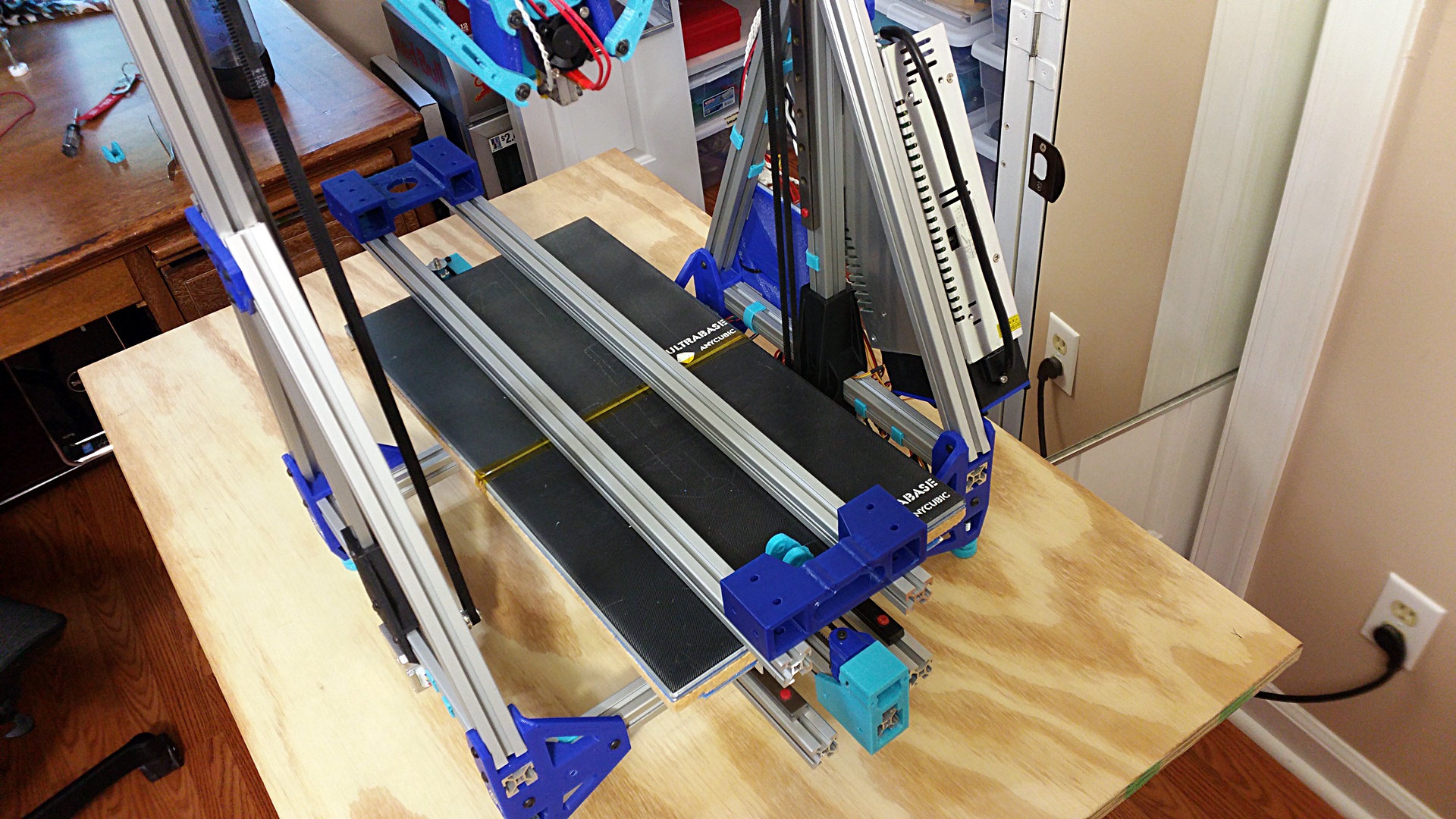

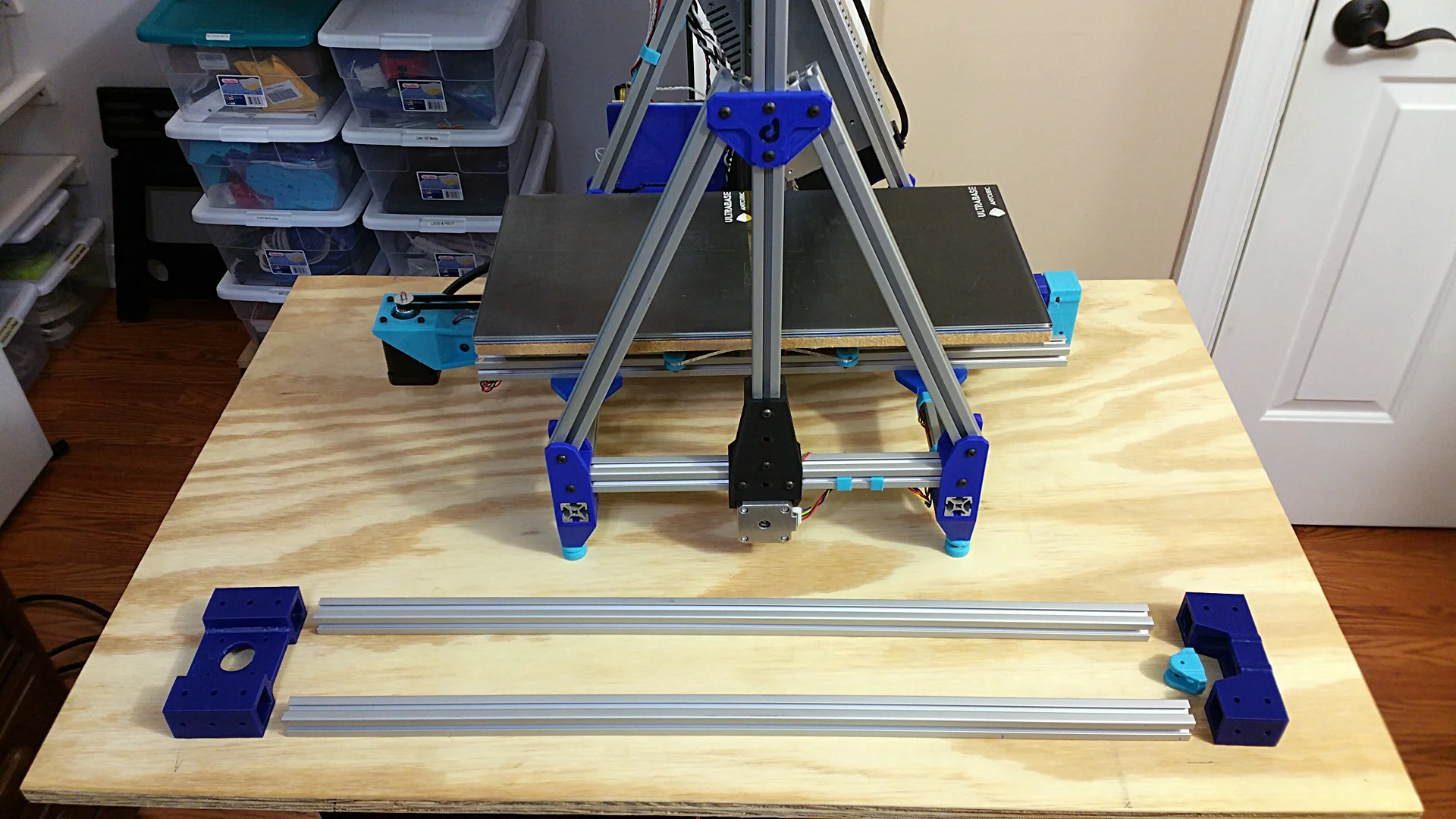

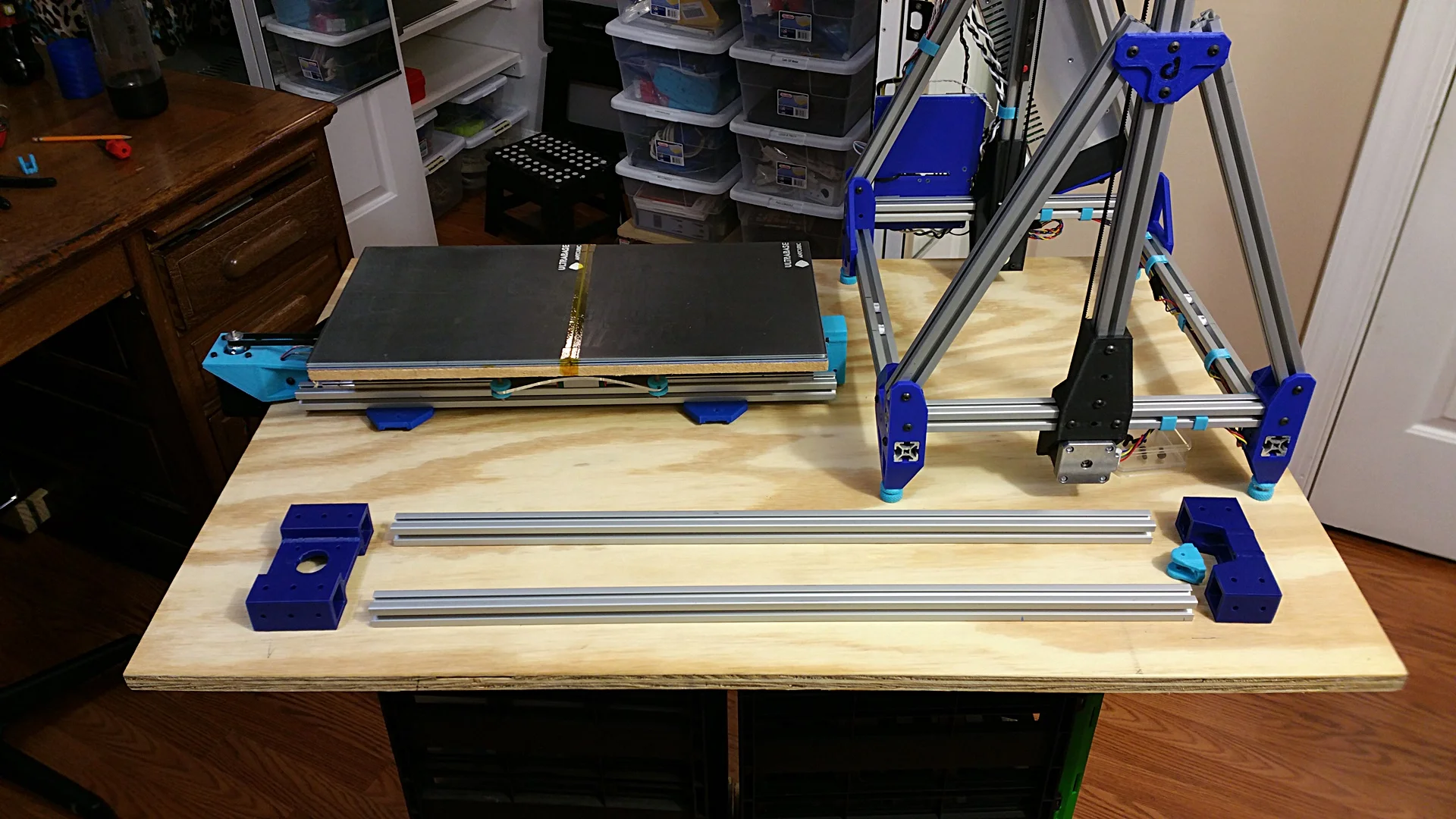

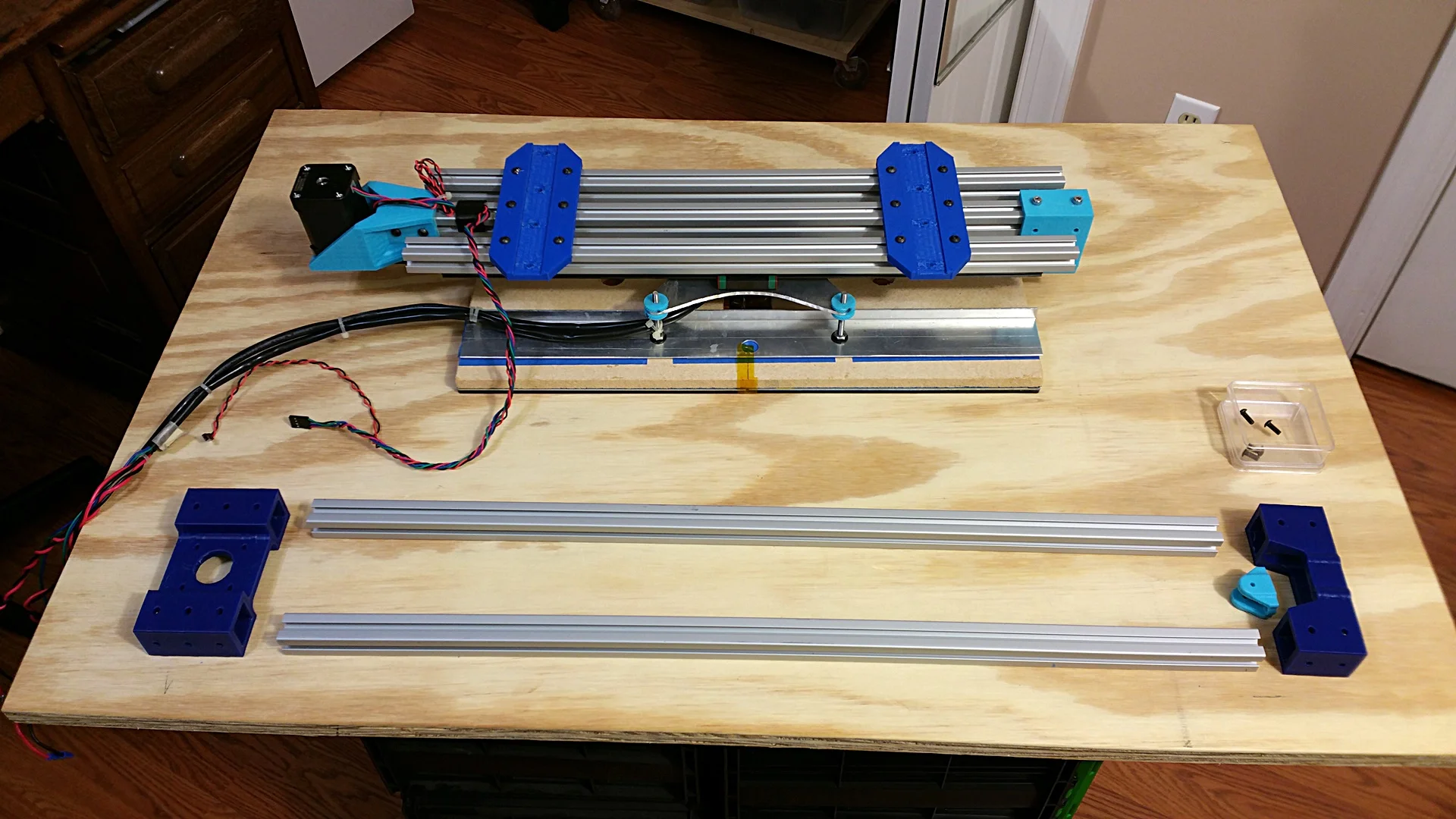

Prototype 2 parts printed and assembled:

New parts have clean movement with no interference!

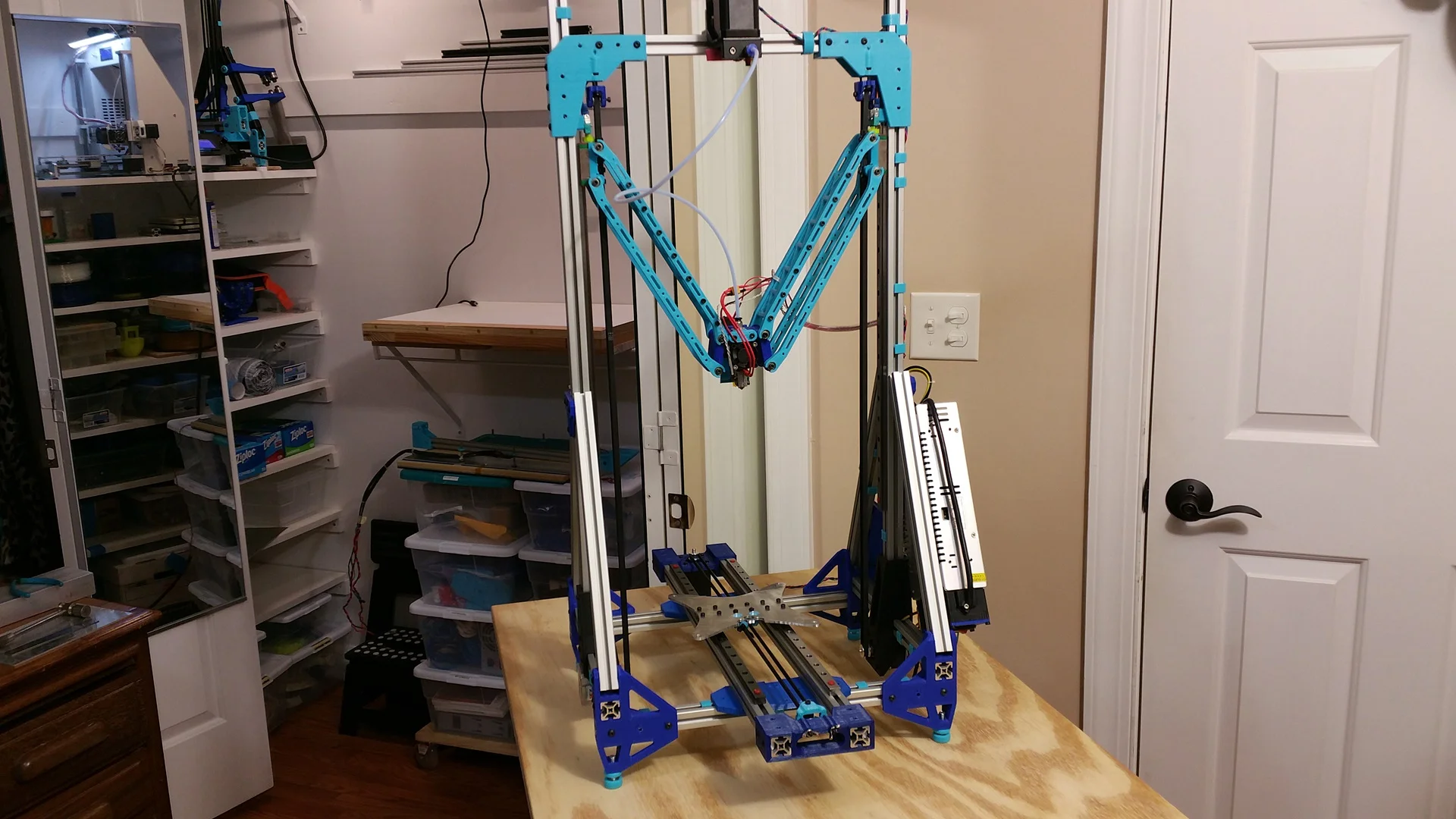

Now ready to add a limit switch and swap this bed onto a functioning machine.

-bornity