The Ultimate Jig Knob

Working in the garage, I often find myself setting up jigs using 80/20, T-slotted channels, fabricated Aluminum brackets and 3D printed parts.

In the past, I always found myself needing more knobs. I used Pronged T-Nuts for a while but I really wanted a universal knob that I could use for all my projects.

I set about designing and refining these Knobs to maximize their flexibility. Early designs were too smooth, so I added knurling. Knobs sometimes needed to be tighter than I could hand torque, or became stuck, thus the hex shaft. Starting the knobs was a pain, so I designed a simple tool to socket in the back of the Knob.

I've come to love this design, and I hope these knobs find their way into your shop!

Download Files

You can get the files here: Thingiverse: Ultimate Jig Knob

Check out the features, specifications and example uses below.

Ultimate Jig Knob Features

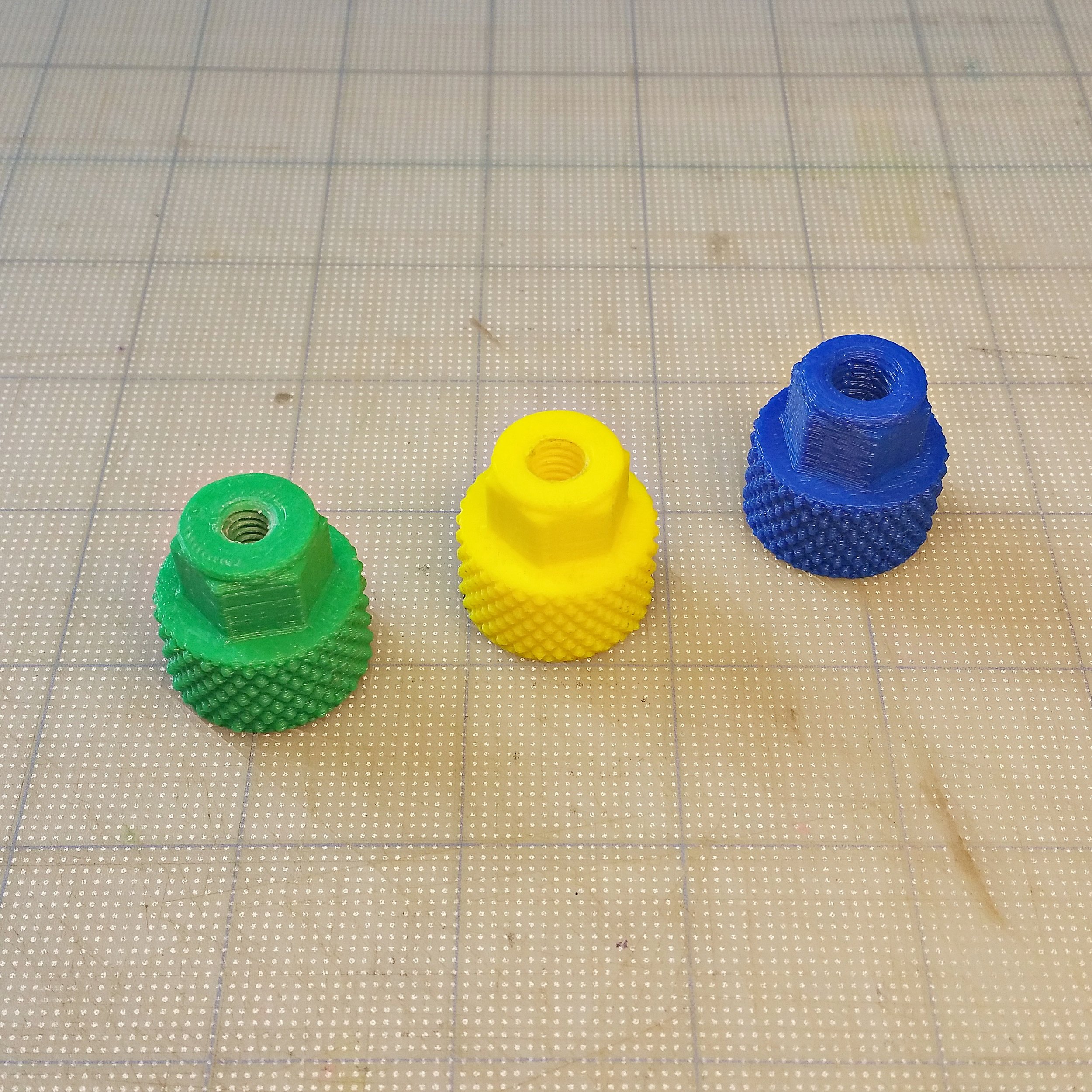

3 Standard SAE SIZES

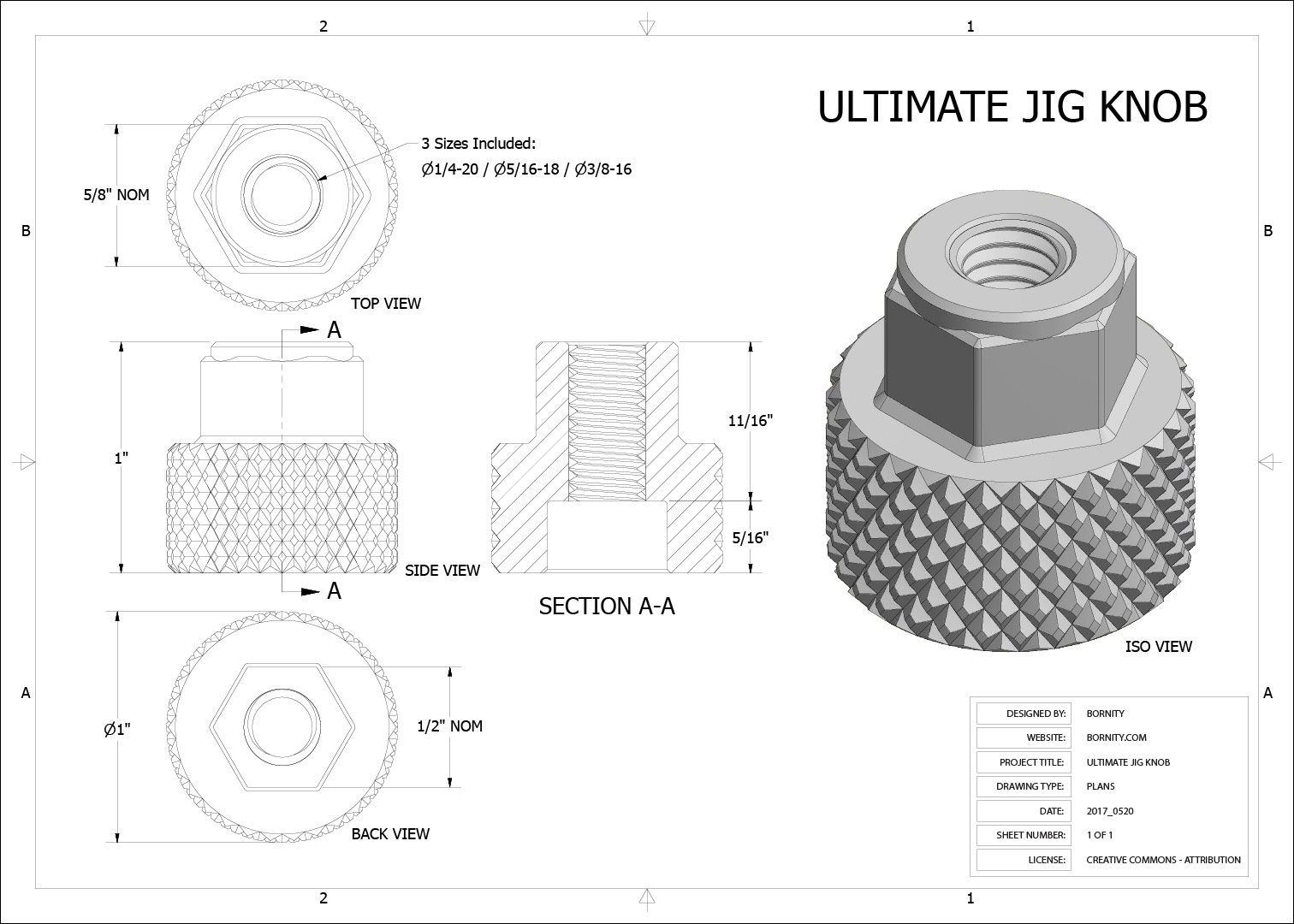

3D Modeled threadforms for 3 common SAE sizes: 1/4-20, 5/16-18 & 3/8-16.

Integrated 5/8" Hex Shaft

Built in 5/8" hex shaft for those times when you need it tighter, or looser.

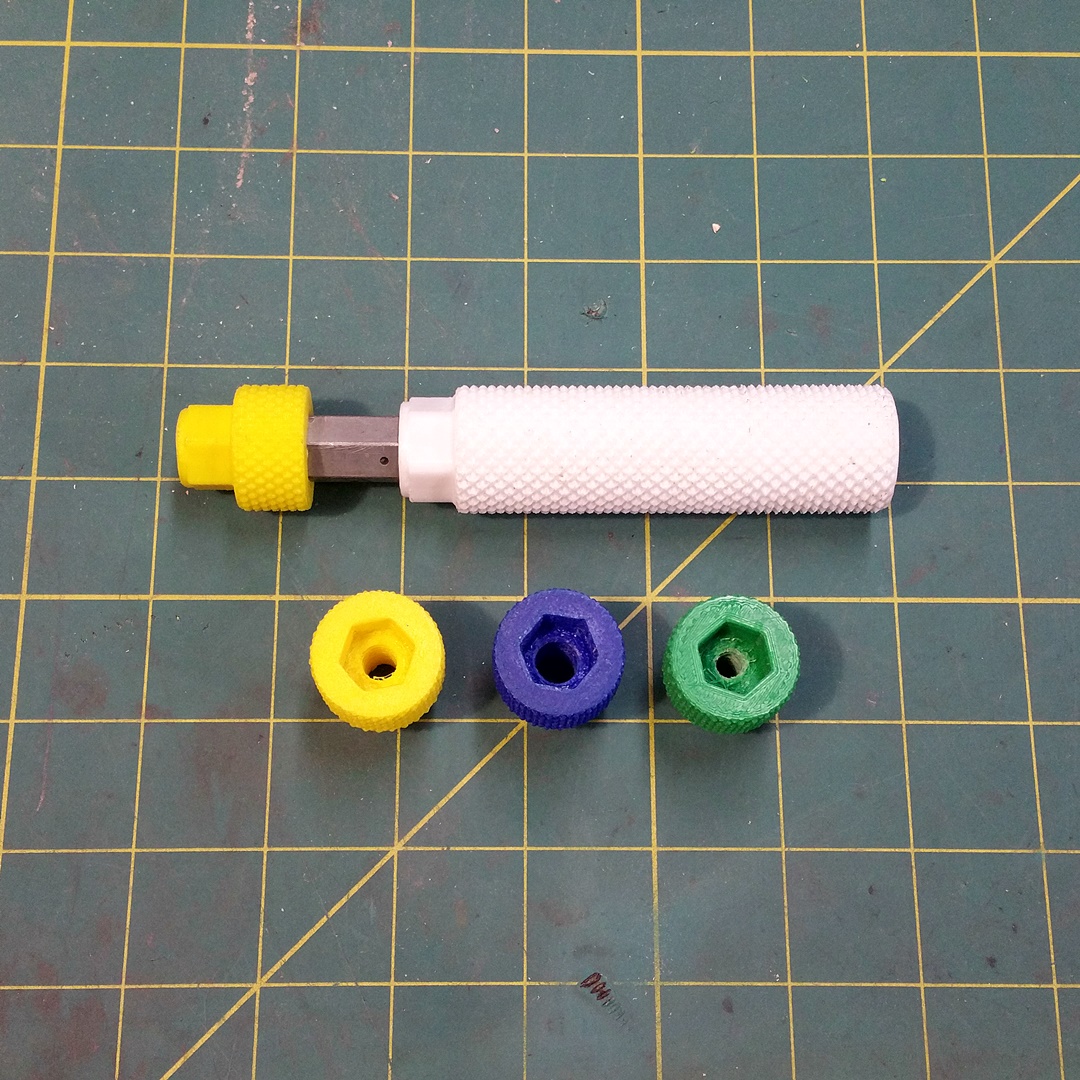

Integrated 1/2" Socket & Tool

Built in 1/2" socket on the rear with easy to build tool makes threading or removing the knob easy.

Metric Version Available Here:

DEMONSTRATION

Integrated 5/8" Hex Shaft

Built in 5/8" hex shaft for those times when you need it tighter, or looser.

Applications

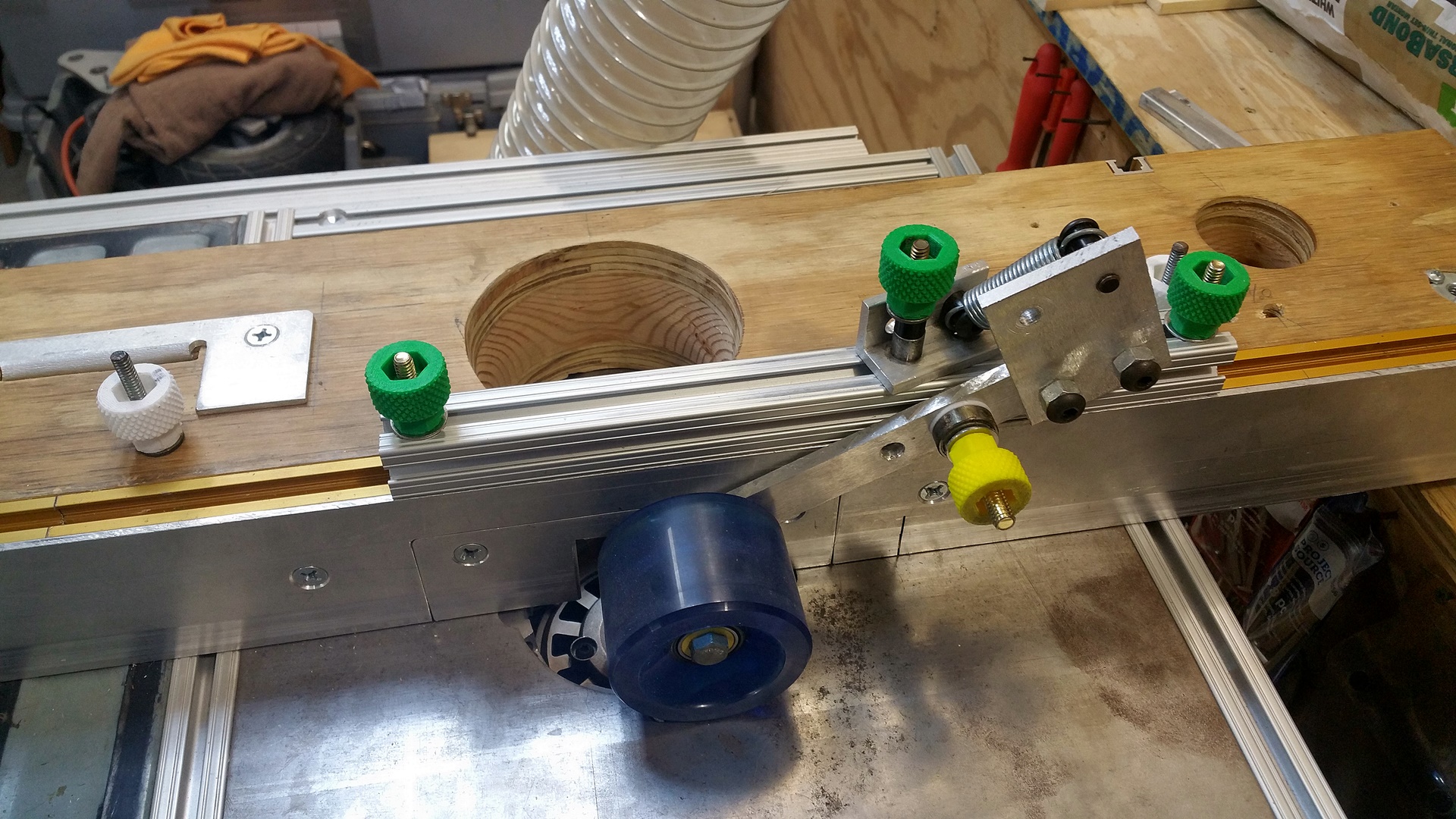

Router Fence and Spring Loaded Hold-down Wheel

Easy adjustment with several Universal Jig Knobs

3D Printer Filament Roll Holder

Easily change the width of the rollers for different width filament rolls.

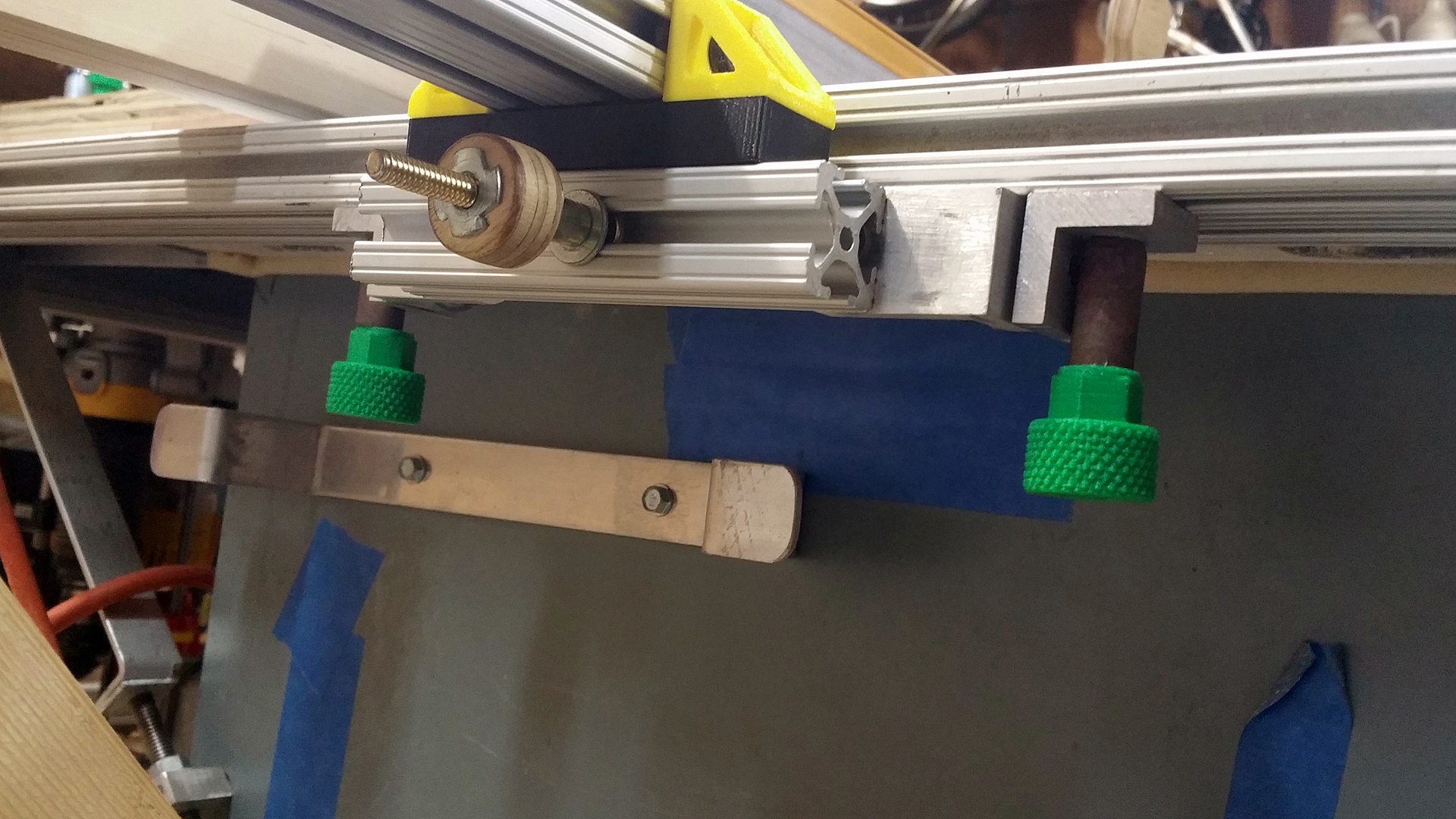

80/20 Miter Gauge

SwaP 80/20 extrusions for different cuts effortlessLy.

Miter Gauge, Adapter Plate and Universal Jig Knobs

Slide in 80/20 and Turn to Lock in Place

Quick Swap Table Saw / Router Table Extension

Quickly Changing the Out Feed Support Position

1" Stand Offs Make the Knobs Easy to Access

Ultimate Jig Knob Tool

Tool Demonstration

Hardware List:

- 1 x ø5/16-18 x 3 1/2” Long Hex Bolt

- 1 x ø5/16-18 x 1 1/8”-1 3/4" Long Hex Coupler Nut (1 1/8 minimum length)

Note: Your local hardware store will sell singles of the bolt and couple

Tool Assembly

Complete Tool

TEchnical Specifications

Fig1: Universal Jig Knob

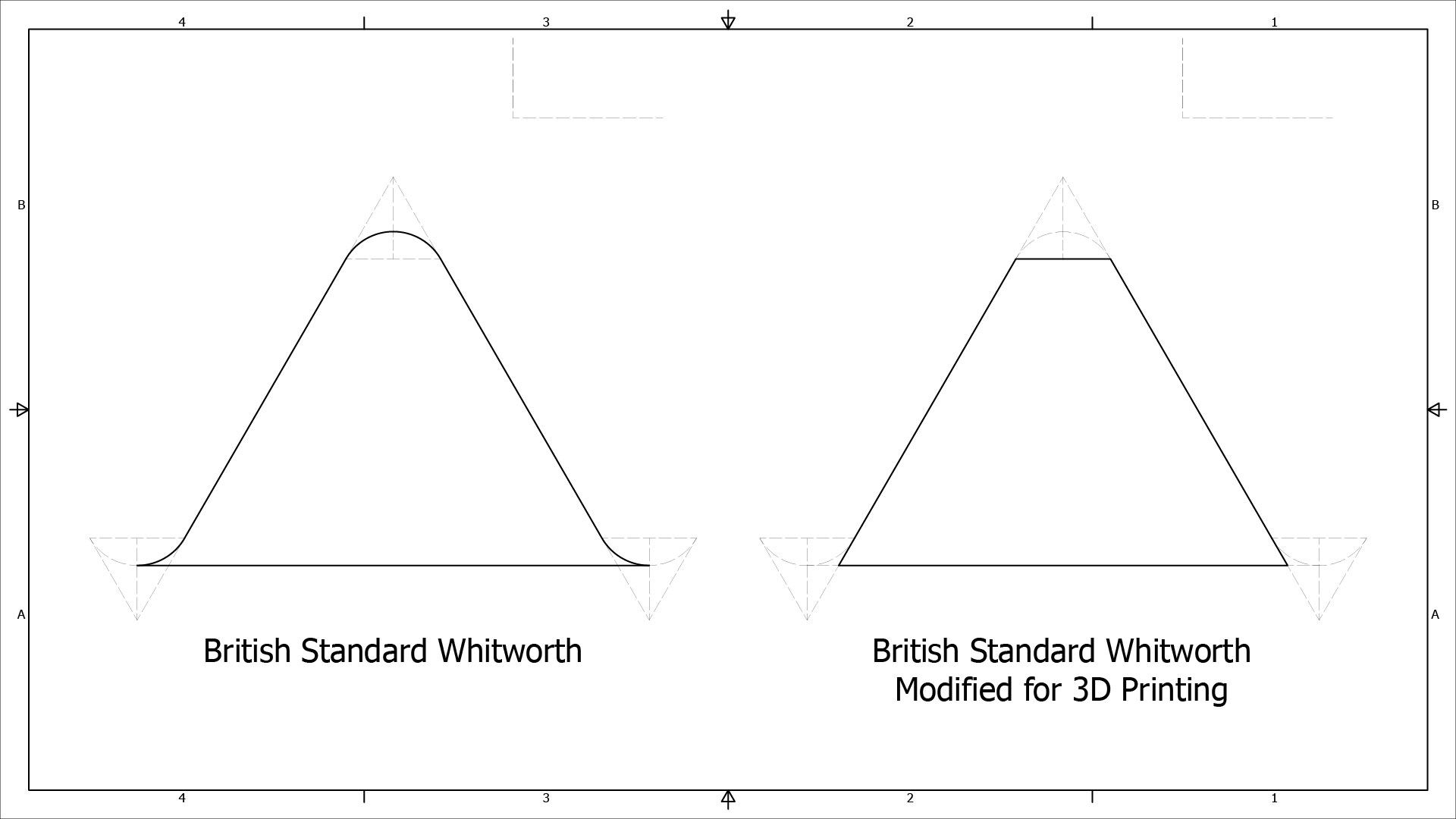

Fig 2: Threadforms

The Thread Design is based on a simplfied version of the British Standard Whitworth with an expansion factor on the overall hole size.

Thread Cutting

Why Tap a Printed Thread?

While the modeled threads are precise enough and toleranced to be functional after printing, it requires a very dialed in printer and thin layers, <0.1mm, to insure clean threads. The thread is a continuous overhang from start finish.

Tapping a printed thread allows you to print faster, thicker layers. I've successfully printed 0.4mm layers with a 0.4mm nozzle, though I recommend 0.2mm layers.

Combination Drill and Tap Bits

A fairly new tooling type to market, Combination Drill and Tap Bits drill the pilot hole, tap and counter sink all in one bit. At ~$10-$15 for a set of 6, they are a steal. They will give you perfect threads every time.

I recommend them for materials like plastics, wood and softer metals. I have broken one tapping 6105-T5 Aluminum - a 1/4-20 bit in the end of a 1010 80/20 extrusion - so use your traditional taps on the harder stuff.

Bonus Cat!

Nala has found a perch in the garage!

Thanks for stopping by!